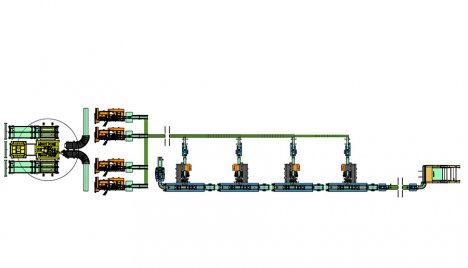

1.the production line equipment composition:

High-precision cutting machine - high-speed weighing intelligent feeding system - high-speed weighing machine - opposite gripping machine - three-dimensional bag packaging machine - double reject automatic checkweigher - plastic bag flat pocket bagging machine - robot Palletizer.

2. the production line process:

The whole rod hanging surface from the drying room enters the high-precision cutting machine and is intelligently cut according to the preset length. The cut surface is cut into high-speed weighing machines through a high-speed intelligent feeding system. After the high-speed weighing and accurate metering, the metered surface is grasped by the opposite gripper into the special bag-making machine of the three-dimensional bag packaging machine. It is packaged by a three-dimensional bag packaging machine. After the packaging, the single-bag finished product is subjected to weight inspection by double-checking the automatic checkweigher, and the qualified products are put into the plastic bag flat pocket bagging machine for large bag packaging. The packaged large bag finished product is sent to the palletizing area via the finished conveyor, and is palletized by the palletizing robot, and then sent to the finished product warehouse to complete the entire production process.

Contact: Ms. Linda

Phone: 18562575187

Tel: 18562552297

Email: info@qdmaoyuanda.com

Add: Qingdao City,Shandong Province,China