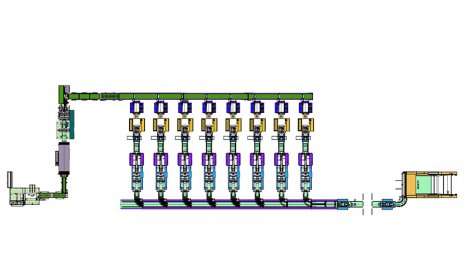

1. the production line equipment composition:

High-precision cutting machine - curved intelligent feeding system - weighing machine - strapping machine - lifting checkweigher - high-tightness universal paper packaging machine - universal sealing machine - robot reversing Equipment - semi-finished conveyor - material, feeding device - fork conveyor line - reciprocating shrink film packaging machine - shrinking furnace - paper bag flat pocket bagging machine - robot palletizer.

2. the production line process:

The whole rod hanging surface from the drying room enters the high-precision cutting machine and is intelligently cut according to the preset length. The cut surface is cut into the weighing machine stations through the curved intelligent feeding system. After accurate weighing by each weighing machine, it will enter the bundling machine station for bundling. The bundled materials are weighted by the lifted checkweigher, and the unqualified materials are automatically removed and transported to the designated location for re-weighing. Qualified materials enter the high-shough universal paper packaging machine for automatic roll wrapping. After packaging, the semi-finished products will automatically enter the general sealing machine for chamfering and sealing. The semi-finished products after sealing are sorted by the semi-finished conveyor, fed into the material processing and feeding device, and automatically fed into the fork conveying line through the reciprocating shrink film packaging machine, and then sent to the shrinking furnace for shrinking and setting. The finished single-package product is packed into a paper bag flat pocket bagging machine for large bag packaging. The packaged large bag finished product is sent to the palletizing area via the finished conveyor, and is palletized by the palletizing robot, and then sent to the finished product warehouse to complete the entire production process.

3. the production line economic benefit analysis:

The paper-packed reciprocating shrink film automatic production line (taking the standard eight-station as an example), the degree of automation is significantly improved. Compared with the traditional artificial production line, the curved intelligent feeding system can save 2 people per shift; the high-tight universal paper packaging machine replaces the manual roll paper packaging, saving 12 people per shift; shifting fork conveying line, reciprocating Shrink film packaging machine, shrinking furnace, can save 3 people per shift; paper bag flat pocket bagging machine can save 2 people per shift; robot palletizer can save 1 person per shift; statistics can save every shift Artificial 20 people.

Contact: Ms. Linda

Phone: 18562575187

Tel: 18562552297

Email: info@qdmaoyuanda.com

Add: Qingdao City,Shandong Province,China