Product name:Automatic Mosquito Mat Packaging Machine

Machine details:

Product Introduction:

The electric heating mosquito-repellent incense tablet dripping automatic packaging machine is our company combined with many years of production and practical experience.

After many improvements by our company's professional and technical personnel, it is finalized and produced and put on the market. The machine has high production capacity

and quality standards, and its design level has fully exceeded other domestic and foreign manufacturers

Product features,

1. The whole machine is controlled by Japanese Omron (or Mitsubishi) PLC programmable controller (40 points), and the speed is controlled by Panasonic inverter.

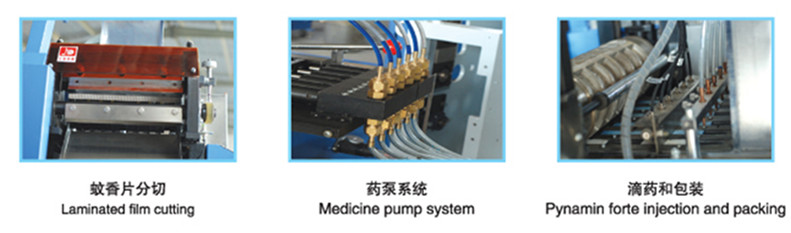

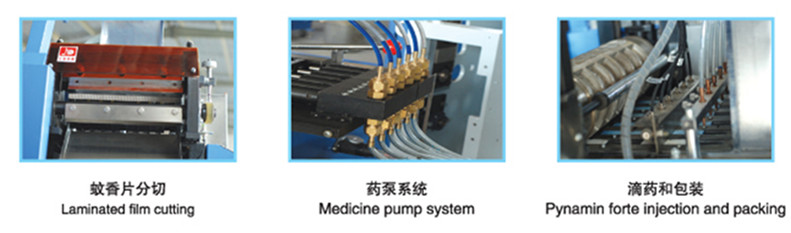

2. The accuracy of dropping medicine is high, and the deviation is controlled within ±5mg. The six paper tablets are administered separately by six pumps (30mg ~ 300mg), each pump can be fine-tuned, the pump body is made of metal, and the service life is long.

3. The product qualification rate is high. The pass rate of white films is ≧99.97%, the pass rate of blue films is 99.96%, and the total pass rate is ≧99.7%.

4. High production efficiency. It can work stably under the condition of 480~630 slices/min.

5. The long-life, low-noise, high-precision rotary shearing method is advanced and scientific. Now it has replaced the previous traditional punching shearing, and its performance is better than Japan's imperial light machine.

6. The cross section adopts electromagnetic clutch, which can be divided into 1-999 rows arbitrarily. Customers can choose according to products to meet their needs for different products.

7. The equipment occupies a small area: the equipment size is only 1230*1200*1650mm, and the net weight: about 650KGS.

8. Low power consumption: total power is about 3kw

Work process:

1.Blank mats(35x22x2.8mm) are stacked vertically by hand and automatically feed blank mats to following section.

2.The blank mat is injected with a fixed amount of Pynamin Forte.

3.The impregnated mats are automatically wrapped by laminated film.

4.The laminated film is cut into sets, each one containing 3 or 15 pieces of mats.

5.The detector function automatically stops the machine if a mat is wrapped without being injected, or it is not wrapped (selective).

Packing: Wooden case

Delivery time: 30 days from the advance payment

Payment: 30% T/T in advance , the balance 70% pay before shipment after inspection

Remark:

1, We responsible for training the technicians of buyer’s company to operate this packing machine

independent in China or our engineer get to buyer’s country for assembling and training, buyer should

pay board and lodging, round trip air tickets, salary and other necessary expense for our engineer in your country

2, We will send you full set of standard spare parts and tooling with packing machine when shipping

3, Warranty: 1 year, after one year, we will supply technical service