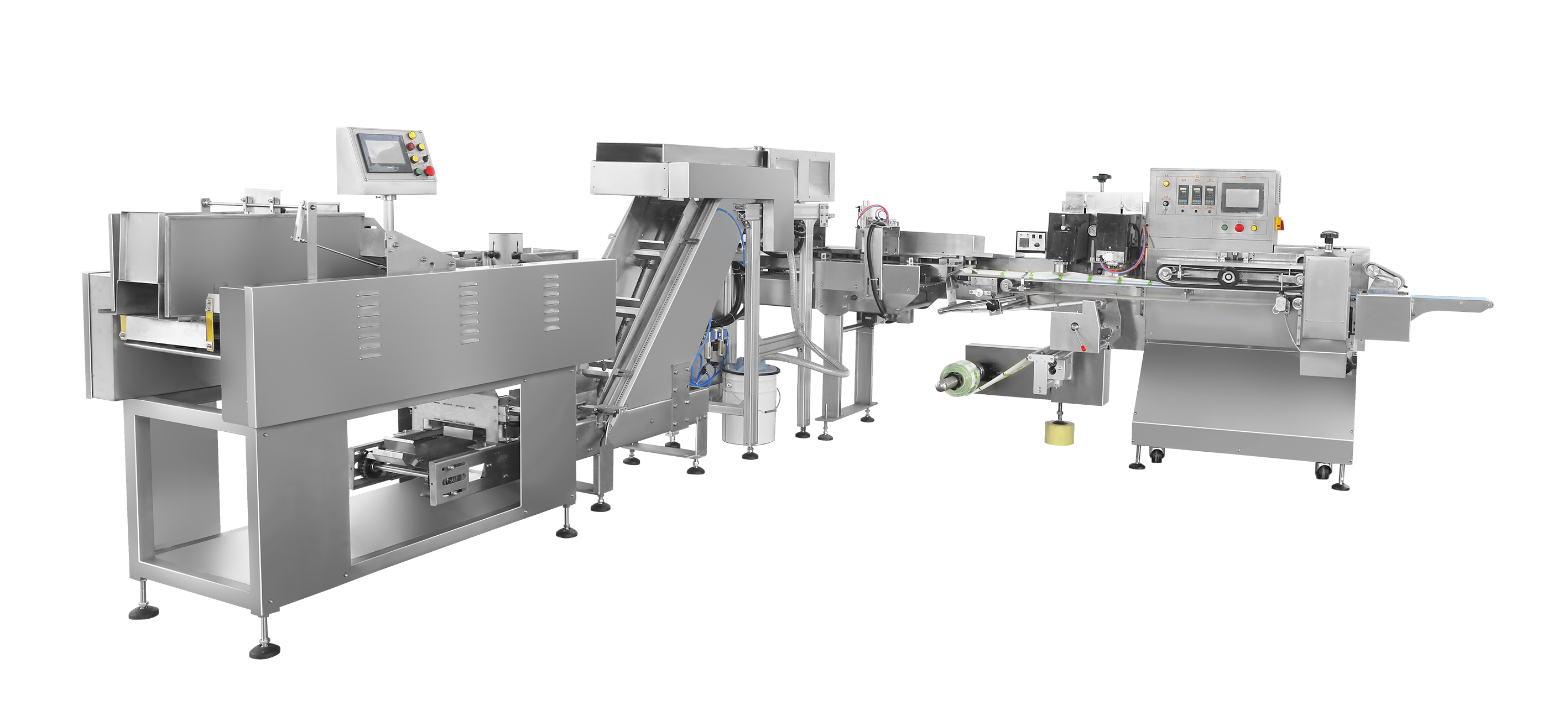

·Product category: touch-screen noodle packing machine

·Product name:Bulk Baby Noodle Weighing And Cutting Packaging Machine

·Contains:

1.weighing machine one set

2.Cutting machine one set

3.Lifting machine one set

4.Packaging machine one set

5.Product conveying line one set

Application :

After weighing, lifting, cutting, transporting, and packaging the loose children's noodles, they are packaged into qualified products using plastic packaging rolls.

Technical Specification:

|

Serial Number |

Project |

Content |

Notes |

|

|

1 |

Packaging finished product shape |

Flat |

|

|

|

2 |

Single package weighing(g) |

20g-40g |

|

|

|

3 |

Noodle length |

100-120mm |

Length after cutting

|

|

|

4 |

Packaging speed |

45 packs/minute |

|

|

|

5 |

Accuracy |

0-2g (Over 95%) |

Noodles should not be too messy or too curved |

|

|

6 |

Shelf life of the weighing machine |

One Year |

|

|

|

7 |

Shelf life of the entire packaging machine |

One Year |

|

|

|

8 |

Equipment size |

4.1×3.5×1.6 L×W×H(meters) |

|

|

|

9 |

Power supply |

220V |

|

|

|

10 |

Power |

5KW |

|

|

|

11 |

The part in contact with noodles (Excluding chutes and scrapers) is made of food grade 304 stainless steel material |

|||

VI.Automation: Fully automated processes such as automatic weighing, lifting, automatic cutting (patent number 201922308052.6), transportation, and packaging of bulk infant and child noodles. High speed saw cutting method is used to ensure that the baby and child noodles are cut neatly and not broken.

VII.Safety: The entire packaging process does not require manual contact with baby and child noodles, ensuring food safety, hygiene, and health. All equipment covers and parts in contact with food are made of food grade 304 stainless steel material.

VIII:Efficiency: Using this device can save 8 people and significantly increase production capacity.

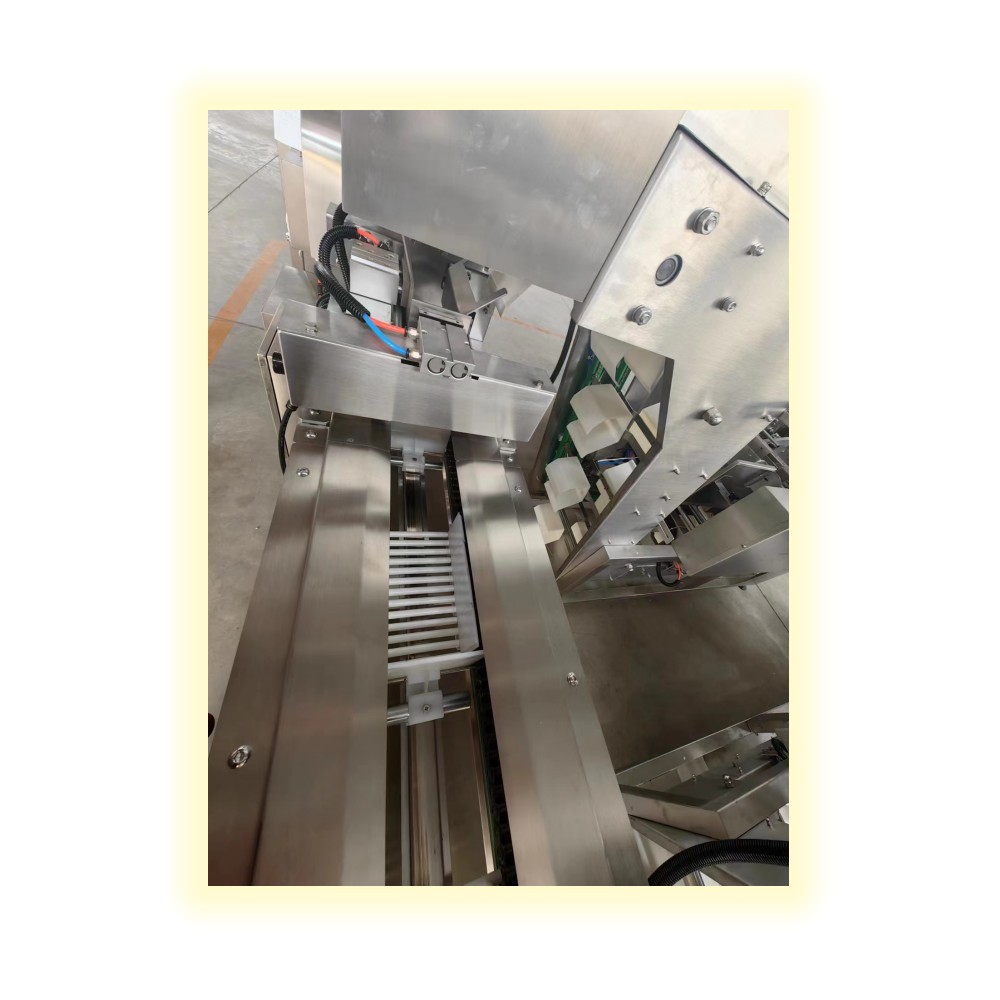

Shipping photos:

Contact: Ms. Linda

Phone: 18562575187

Tel: 18562552297

Email: info@qdmaoyuanda.com

Add: Qingdao City,Shandong Province,China