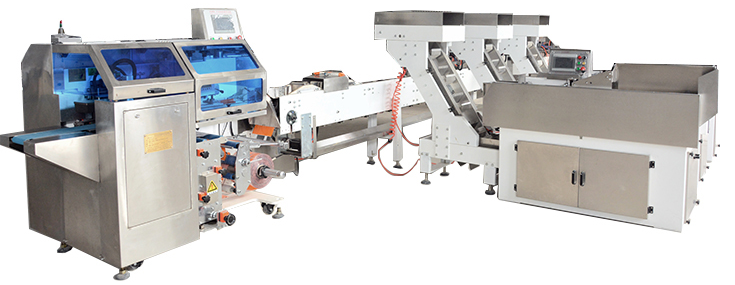

·Product category: touch-screen noodle packing machine

·Product name:Spaghetti Dry noodles Rice noodles Packaging Machine (One For Three)

·Contains:

1.weighing machine 3 sets

2.Lifting machine 3 sets

3.Packaging machine 1 set

4.Product conveying line 1 set

Application :

After weighing and conveying, the bulk noodles spaghetti Pasta and other strips are automatically packaged into ordinary flat bags, with smooth sealing, overall beauty and high yield.

Technical Specification:

Package object

The strip-shaped material (such as noodles.spaghetti)

Packing capacity

30-60 bags / min

Packaging specifications

200g~500g;500g~1000g

Measurement Accuracy

(according to the material strip quality and packing quality differances)

Packaging

OPP/PEQPP/AL/PE suitable for heat sealing packaging material

Power supply

Single-phase AC 220 V/50 Hz

Machine Details:

Suitable for automatic weighing, conveying, and packaging of long bulk materials such as noodles, spaghetti, etc.

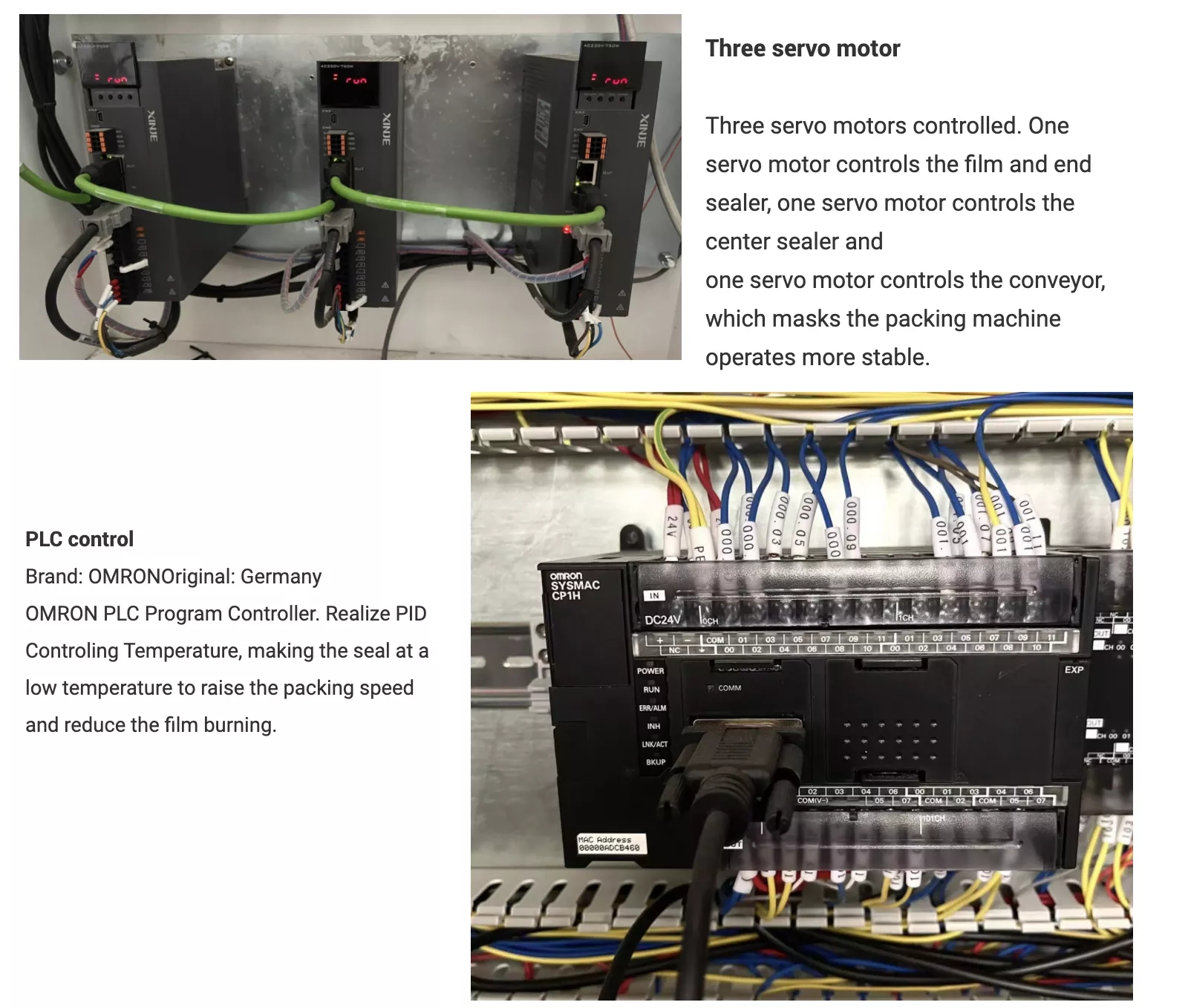

1. Intelligent, digital servo motor control system.

2. Double drive longitudinal seal, automatic opening and closing type structure.

3. The cross-sealing and cutting center can be adjusted with the height of the package.

4. Feeding position can be adjusted at any time during operation.

5. LCD can set and display operation status, parameters, and faults.

6. Conveying part has a compact structure and adopts a box type structure, which solves the disadvantages of the onventional scraper structure that needs to be changed and exposed frequently.

7. With a unique noodle tidy device to ensure the qualified rate of the finished product of noodle packaging

8. With an empty package detection function, saving packaging costs

9. Color-mark tracking points are automatically positioned and followed automatically; bags are automatically measured and memorized.

10. Domestic initiative, patented product.

Shipping photos:

Contact: Ms. Linda

Phone: 18562575187

Tel: 18562552297

Email: info@qdmaoyuanda.com

Add: Qingdao City,Shandong Province,China