·Product category: touch-screen noodle packing machine

·Product name:Automatic multi scale bundling and packaging production line for Spaghetti/Dry noodles

·Contains:

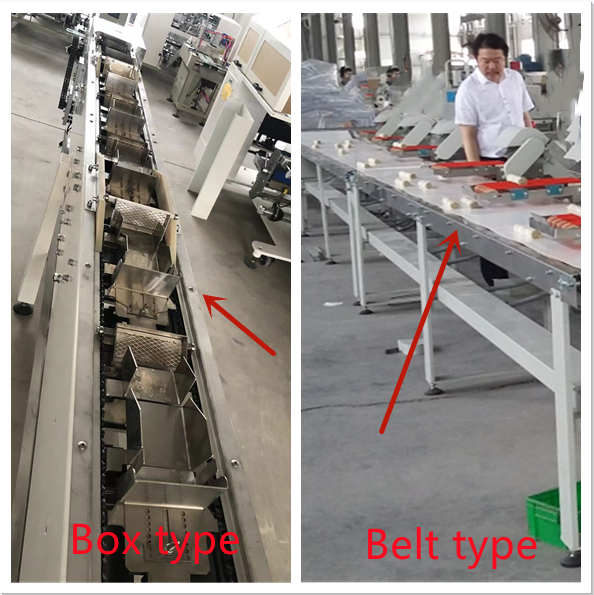

Weighing machine , Bundling machine , Lifting machine , Feeding conveying line , Material Tiding line , Packaging machine.

Application :

Through the process of automatic weighing, automatic binding, automatic conveying, automatic sorting, automatic packaging and other processes, the bulk noodles, spaghetti, Rice noodles and other strips are packaged into flat, three-dimensional shapes or high-end products with supporting boxes through plastic packaging film;According to customer requirements, multiple production lines can be added.

Technical Specification:

Package object

Dry noodles, pasta and strip material

Package length

180-260mm(200g-500g); 240-260mm(500g-1000g)

Packaging speed

15-35 bags /min

Surement range

200-500g, 200-1000g

Equipment size

13000 x 5500 x1650 mm

Power supply

AC 220V/ 50-60 HZ/12KW

Machine Details:

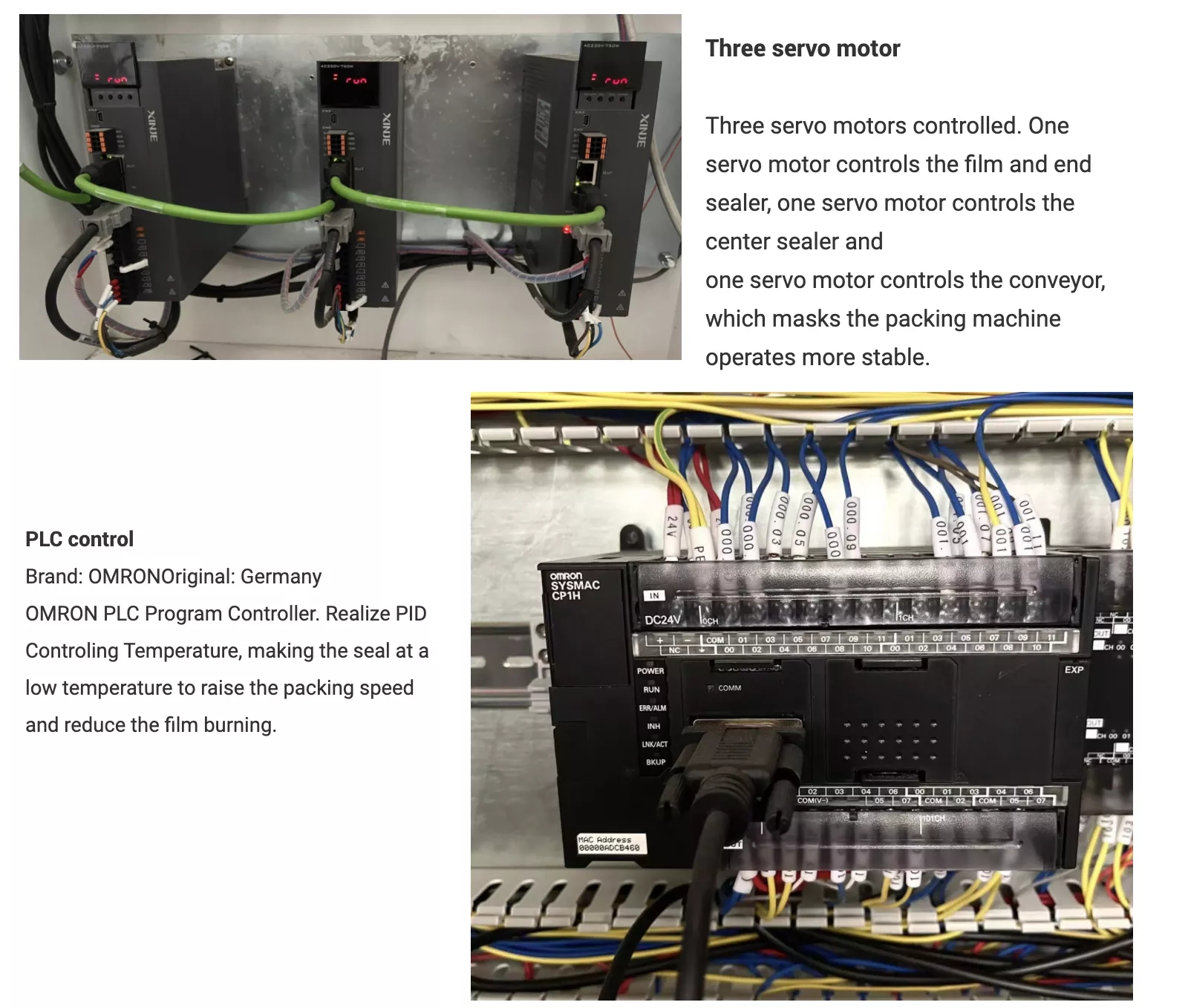

1. The production line adopts well-known electrical components and PLC control, and the drive part is composed of several servo motors and frequency conversion motors, which can realize the step-less speed control of the whole production line, dynamic adjustment of the operation process and other intelligent operations, simplify the mechanical rotation system, make the equipment operation more stable and reliable, and reduce the mechanical noise and mechanical failure rate.

2. Using the LCD touchscreen control panel, the specific packaging parameters of the product can be set, the operation is convenient and intuitive, and it has the function of automatic monitoring, which automatically diagnoses the fault during the production line operation and alarms. Consequently, the packaging speed is greatly improved and the product rejection rate is reduced.

3. The production line has fast packaging speed and high production efficiency, packaging 20-40 tons of finished products per day, and the packaging effect are exquisite and high-grade.

4.The spatial structure of the whole production line is reasonably designed, which is convenient for customers' daily sanitation and cleaning, and maintenance is simple and convenient.

Shipping photos:

Contact: Ms. Linda

Phone: 18562575187

Tel: 18562552297

Email: info@qdmaoyuanda.com

Add: Qingdao City,Shandong Province,China